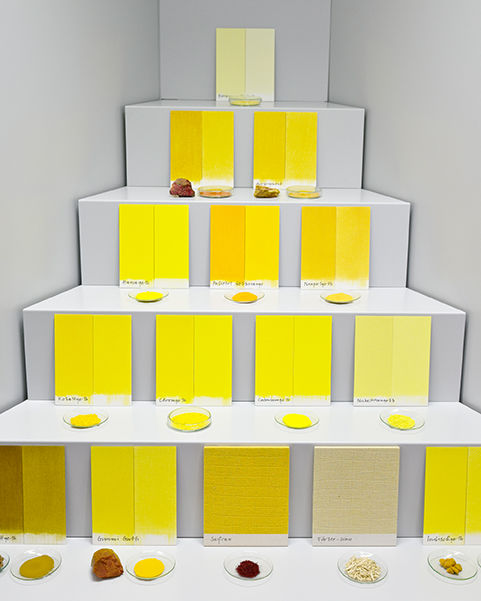

Colour octagon at Museum Wiesbaden. Photo: Museum Wiesbaden / Ed Restle

With its 120 colour samples, the colour octagon in the permanent exhibition of the Natural History Collections is a true crowd-pleaser

Various greens, blues, reds, and yellows – 15 variants of each, on painted or dyed fabric samples – radiate their brilliance on one of the tiers of the octagonal display case. These four colours are perceived by the human eye as ‘pure’ colours (or spectral colours). Then there are earth tones such as ochre and umber. Displayed in further compartments are special lustre effects, along with the structural colours, and 15 samples each of the diverse tones of black and white. Although it is the pigments – the water-insoluble colorants – that predominate in the display, the selected dyestuffs narrate a short history of the art of dyeing: beginning with saffron, whose cultivation has been documented since antiquity, all the way to fuchsine, one of the first synthetic dyes. Incidentally, there are far more natural than artificial dyes: alongside a small number of animal sources, the key reference work Handbuch der Naturfarbstoffe (Handbook of Natural Dyes) lists at least 200 different plants and fungi as plant dyes.

While the early use of pigments is documented through cave paintings (the oldest of which being on the Indonesian island of Sulawesi and in Spain, both more than 40,000 years old), we lacked similarly early evidence for the art of dyeing – until very recently that is. This absence of material evidence hardly seems surprising, since natural fibres, along with leather, are biodegradable. But in 2009, tiny fibre remnants found on the floor of a loamy cave in Georgia (in the Caucasus) furnished fresh evidence: as far back as 32,000–19,000 years ago, humans not only plied fibres into threads, but seem to have dyed them as well: for a number of these tiny fibre remnants were indeed coloured.

Compared with natural pigments, dyes are far more difficult to obtain. Very few (an example being saffron) can dye fabrics directly in an aqueous solution. Most natural colorants are absorbed by textile fibres only after these have been treated with a mordant, which is to say, a metallic salt such as aluminium, iron, or copper. As a result, these mordant dyes do not wash out, and the colours have greater luminosity and intensity. Another dyeing procedure requires vat dyes such as indigo or purple. Here, the water-insoluble natural product harvested from a plant or gastropod is converted into water-soluble form. In an alkaline vat, one using urine for example, the fabric absorbs the dye before it is finally converted into a water-insoluble form again through contact with the air, which is to say through oxidization.

While the origins of the art of dyeing remain obscure, research into early civilizations has shed light on its historical development. From the Egyptians to the Incas, all ancient civilizations had knowledge of both plant and animal dyes. And these ancient dyes remained highly coveted until the emergence of synthetics.

This is indigo from India, the blue dye that in the 17th century supplanted one of the oldest native European plant dyes: woad. Also originally sourced from India were the Rubia, better known as madder, which dyed fabrics red. Introduced into Europe with the discovery of the east coast of South America, however, was the dye of the redwood of the Brazilian Pernambuco tree. In the Mexican region today known as Oaxaca, the Spaniards observed the cultivation of scale insects on prickly pear cactuses and the production of dye through the boiling of the insects once dried, which was then traded in Europe as carmine.

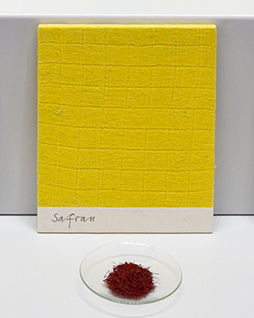

Latest genetic investigations have identified the Aegean as the botanical homeland of saffron – a species of crocus that blossoms in autumn. For 3000 years, saffron has been cultivated as a medicament, a spice, and a plant dye. The earliest textual evidence, 3000 years old, was inscribed in cuneiform script on clay tablets. Frescoes from the Minoan culture found on the Greek islands of Santorini and Crete depict Crocus sativus plants. During the early Middle Ages, its cultivation spread throughout Central Asia and the Mediterranean region. Its first recorded use in Spain dates to the 9th century. Later, there were growing centres in nearly all European lands. The name of the English town Saffron Walden testifies to its successful cultivation and trade in England during the 16th and 17th centuries. Emigrants from Europe, meanwhile, brought saffron to America. Most of the saffron sold today comes from Iran, while Spain (where it is

widely used in paella) accounts for only a small proportion of world trade. While saffron is used today mainly as a spice and food colouring, and is prized by some as a medicinal tea, it was valued as a vegetable dye until the emergence of synthetic dyes. Of the flower, only the intense reddish-brown and red-to-purple coloured stigmas – known as threads – contain the colourant itself. To this day, the flowers, which blossom only briefly, are harvested by hand, once annually, and the threads sorted and dried. Altogether 120,000 to 200,000 blossoms must be harvested to make just 1 kg of dried saffron.

It is only during the drying of the saffron threads that the primary colouring agent, called protocrocin, breaks down, first into the powerful yellow dye crocin, secondly into the flavouring agent picrocrocin. Developing during storage, as the process of decay proceeds, is another typical flavouring agent and odorant known as safranal. The colourant is one of the few direct dyes, and can be used in a simple water basin or vat. Through this process, the wool acquires an orange-yellow hue.

In contrast to indigo or redwood, saffron was a rarity in the dyeing vats, and was reserved for luxurious or even sacred fabrics. For everyday yellow garments, there existed alternatives, such as dyer’s rocket (Reseda luteola) from West Asia and the Mediterranean region. Incidentally, discoveries of Neolithic seeds suggest that dyer’s rocket was used as a dye more than 8000 years ago.

The dyeing of fabrics with natural substances is an ancient cultural technology, and one that is kept alive by a few committed individuals. One example is the Steins, a couple from Neckeroda in Thuringia, who produced dyed colour samples using wool and silk fabrics for Museum Wiesbaden, now displaying their former radiance following extensive reconditioning. Currently, however, the display pieces provide a striking demonstration of the difference between colourfast and non-colourfast agents.

A comparison between the sample dyed with cochineal, which retains its intense luminosity, and the piece dyed using redwood shows why the insect dye has always been so highly prized in Europe.

With the discovery of synthetic pigments in 1857, the world of colorants – along with its production areas, commercial routes, and dyeing operations – was turned upside down. Pivotal in this ‘disruptive’ growth industry was the Main region.

Around 1900, five of the eleven most important centres of the German chemical colourant industry were located in the Main region in Hessen: Biebrich, Höchst, Frankfurt, Offenbach, and Mühlheim. Pioneers in the production of coal-tar dyes set up shop here between 1856 and 1879 with small operations staffed by just a few workers. With the discovery of fuchsine in 1858, all of these firms commenced production. By around 1867, the number of synthetic dyes was already around 500, and by 1914 had risen to 1400.

Fuchsine is still produced, and although a sample can be seen in the colour octagon, the carcinogenic substance is used today only to dye tissue samples in laboratories. Dye production and dyeing operations have long since relocated from the Main region to other countries. From an ecological perspective, the dye works find themselves in a difficult position.

They require a great deal of water and thermal energy, and work in some instances with materials that are hazardous to both the workers and the environment. Strict laws are in place to limit the risk of contamination. The Standard 100 by Oeko-Tex is an independent testing system, in force since 1992. In the town of Hirschhorn in southern Hessen, one of the last German dyeworks processes wool, yarn, and ribbons in conformity with the industry standard. But unlike natural-dye works, such operations continue to require excessively high water consumption.

Dipl. Biol. Susanne Kridlo

Translation: Lance Anderson